Details:

Feature:

Maximum temperature 140°C=280°F

Noise level range 75~100dBA

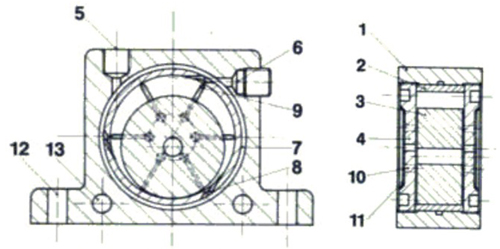

These compact pneumatic vibrators are simple in design and yet capable of deliverieng very high centrifugal forces.

The body is machined from an extruded aluminium section, inside of which a precision steel roller rotates, it is retained by two special high impact plastic end plates. For easy mounting, the body has four holes, two horizontal and two vertical.

Air is introduced through one of two inlet ports drilled at right angles to each other in the body. These inlet ports are tapped with a standard pipe thread and a pipe plug is provided for sealing the one not used. The air is exhausted through the special high impact plastic end plates whose design incorporates an air silencer.

Application:

Series R high frequency pneumatic roller vibrators provide a new approach in the movement of fine materials. Being pneumatically powered, the frequency can be controlled by the regulation of air pressure.

Examples of their uses inculde:

- Emptying hoppers

- Agitation of small particles

- Moving of fine powders

- Compaction of plastic and concrete in moulds

|

Performance: |

|

Model |

Frequency |

Centrifugal force* |

Air consumption / Minute |

|

V.P.M. x 1000 |

|

2 |

4 |

6 |

2 |

29 |

4 |

58 |

6 |

87 |

2 |

29 |

4 |

58 |

6 |

87 |

|

Bar |

Bar |

Bar |

Bar |

PSI |

Bar |

PSI |

Bar |

PSI |

Bar |

PSI |

Bar |

PSI |

Bar |

PSI |

|

29 |

58 |

87 |

N |

LBS |

N |

LBS |

N |

LBS |

Ltr. |

CF |

Ltr. |

CF |

Ltr. |

CF |

|

PSI |

PSI |

PSI |

|

|

|

|

|

|

|

|

|

|

|

|

|

R-50 |

25 |

35 |

36 |

1.07 |

240 |

2.92 |

657 |

4.22 |

950 |

100 |

3.5 |

145 |

5.1 |

195 |

6.9 |

|

R-65 |

19 |

21 |

26 |

2.73 |

614 |

4.83 |

1.089 |

6.12 |

1.377 |

200 |

7 |

300 |

10.6 |

400 |

14.1 |

|

R-80 |

15.5 |

18.5 |

19 |

3 |

675 |

6.09 |

1.37 |

7.45 |

1.676 |

290 |

10.2 |

430 |

15.2 |

570 |

20.1 |

|

R-100 |

11 |

14 |

16 |

3.75 |

844 |

6.75 |

1.519 |

8.9 |

2.003 |

370 |

13 |

550 |

19.4 |

730 |

25.8 |

|

R-120 |

10 |

11.5 |

12.5 |

8 |

1.8 |

10 |

2.25 |

12.5 |

2.812 |

500 |

17.6 |

730 |

25.8 |

970 |

34.2 |

* Data obtained with a Kistler 3-axis dynamometer on a heavy laboratory test block and displayed by Kistler control monitor (COMO). Frequency and force will decrease on a less rigid mount. Specifications subject to change without notice or obligation.

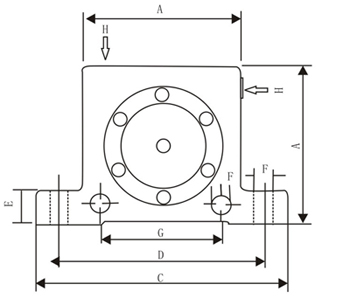

Dimension:

|

Model |

A |

B |

C |

D |

E |

F |

G |

thread |

Weight |

|

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

kg |

|

R-50 |

50 |

2 |

29 |

1.1 |

86 |

3.4 |

68 |

2.7 |

12 |

0.5 |

7 |

0.3 |

40 |

1.6 |

G1/8" |

0.24 |

|

R-65 |

65 |

2.6 |

37 |

1.5 |

113 |

4.5 |

90 |

3.5 |

16 |

0.6 |

9 |

0.4 |

50 |

2 |

G1/4" |

0.545 |

|

R-80 |

80 |

3.2 |

43 |

1.7 |

128 |

5 |

104 |

4.1 |

16 |

0.6 |

9 |

0.4 |

60 |

2.4 |

G1/4" |

0.95 |

|

R-100 |

100 |

3.9 |

52 |

2.1 |

160 |

6.3 |

130 |

5.1 |

20 |

0.8 |

11 |

0.4 |

80 |

3.2 |

G3/8" |

1.81 |

|

R-120 |

120 |

4.7 |

77 |

3 |

194 |

7.6 |

152 |

6 |

24 |

0.9 |

17 |

0.7 |

no lateral hole |

G3/8" |

4.26 |

|

Construction:

1 - Extruded aluminum alloy body

2 - Cast iron liner

3 - Steel alloy roller

4 - Plastic end plates

5 - Vertical air inlet

6 - Horizontal air inlet

7 - Air groove

8 - Inlet jets

9 - Exhaust ports

10 - Exhaust diffuser

11 - Silencer plate

| |